1890

1897

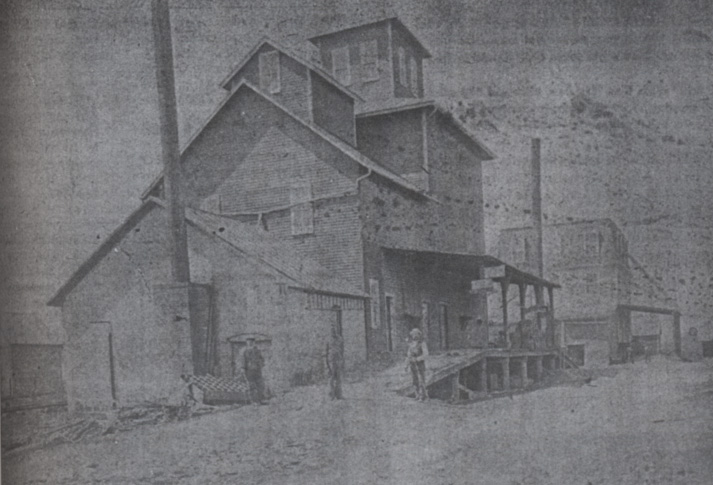

Six years before the Village of Pigeon was incorporated: three businessmen, J.W. Leipprandt, E.C. Leipprandt, and Fred Reithel, formed the Pigeon Milling Company.

1910

1913

A group of farmers formed a committee consisting of James Foster, George Zpfaff, and Jacob Geiger to organize and solicit a stock offering amounting to $50,000.00. The stock solicitation was accomplished over a two year period.

1915

November 26th the stockholders consisting of farmers in the area formed the Cooperative Association purchasing the buildings and land of the Pigeon Milling Company for $25,000.00. The first board members were: John Ullrich, Fred Fisher, John Yackle, Chris Ropp, and Harry Warren. Elevator storage capacity at the time was 30,000 bushels.

1918

The appointment of Henry Clabuesch as the new General Manager brings new skills to the organization.

1930

1930

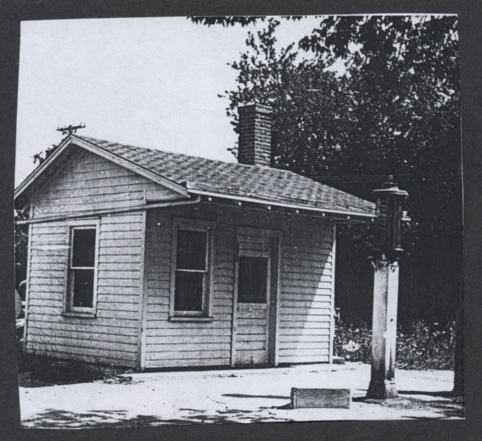

The Cooperative ventures into the fuel oil business and also opens a small two pump gas station as the internal combustion engine for automobiles and farm tractors were here to stay. Sales volumes this year from oil and gas $14,500.00.

1939

Henry Clabuesch steps down as general manager after 21 years of service. Alfred Roberts, who had been the bookkeeper for 13 years, is now appointed the new GM. The company decides to build a Super Service Station providing gasoline, tires, fuel oil, and repair services. Delivery trucks were also purchased to services the farmer’s needs.

1950

1950

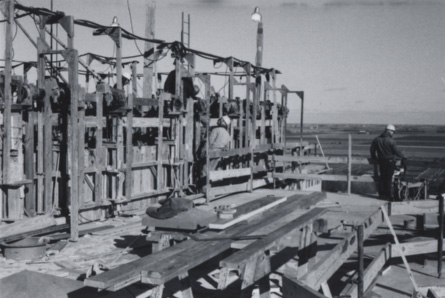

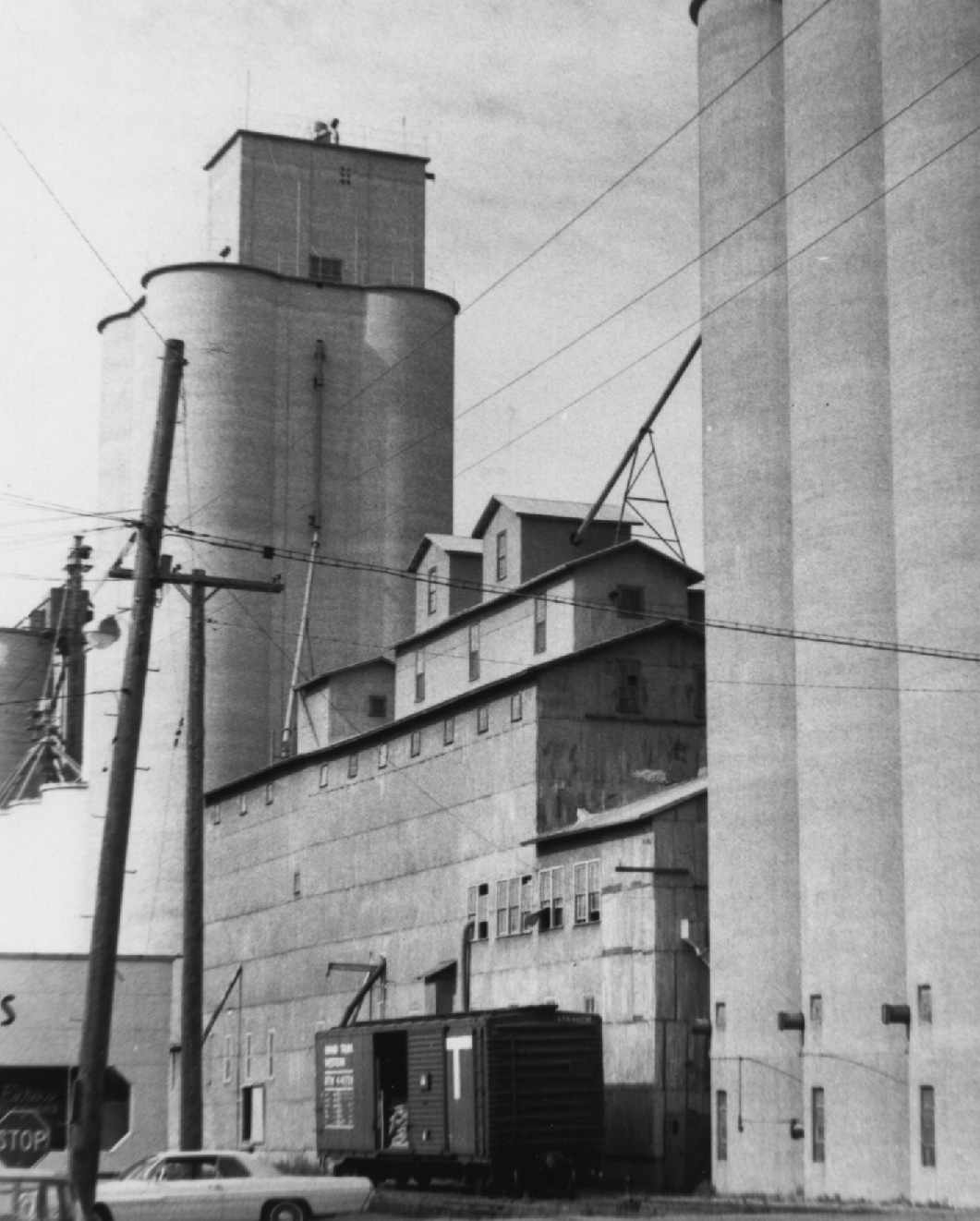

The first concrete silos were built across the street from the original site of the milling operations. These were the first continuous pour concrete structure silos. The capacity of these silos is 160,000 bushels.

1956

A new corn handling facility was constructed. Elevator capacity is now 260,000 bushels. At this time corn was the leading cash crop.

1960

1963

More concrete silos are constructed bringing elevator capacity to 430,000 bushels.

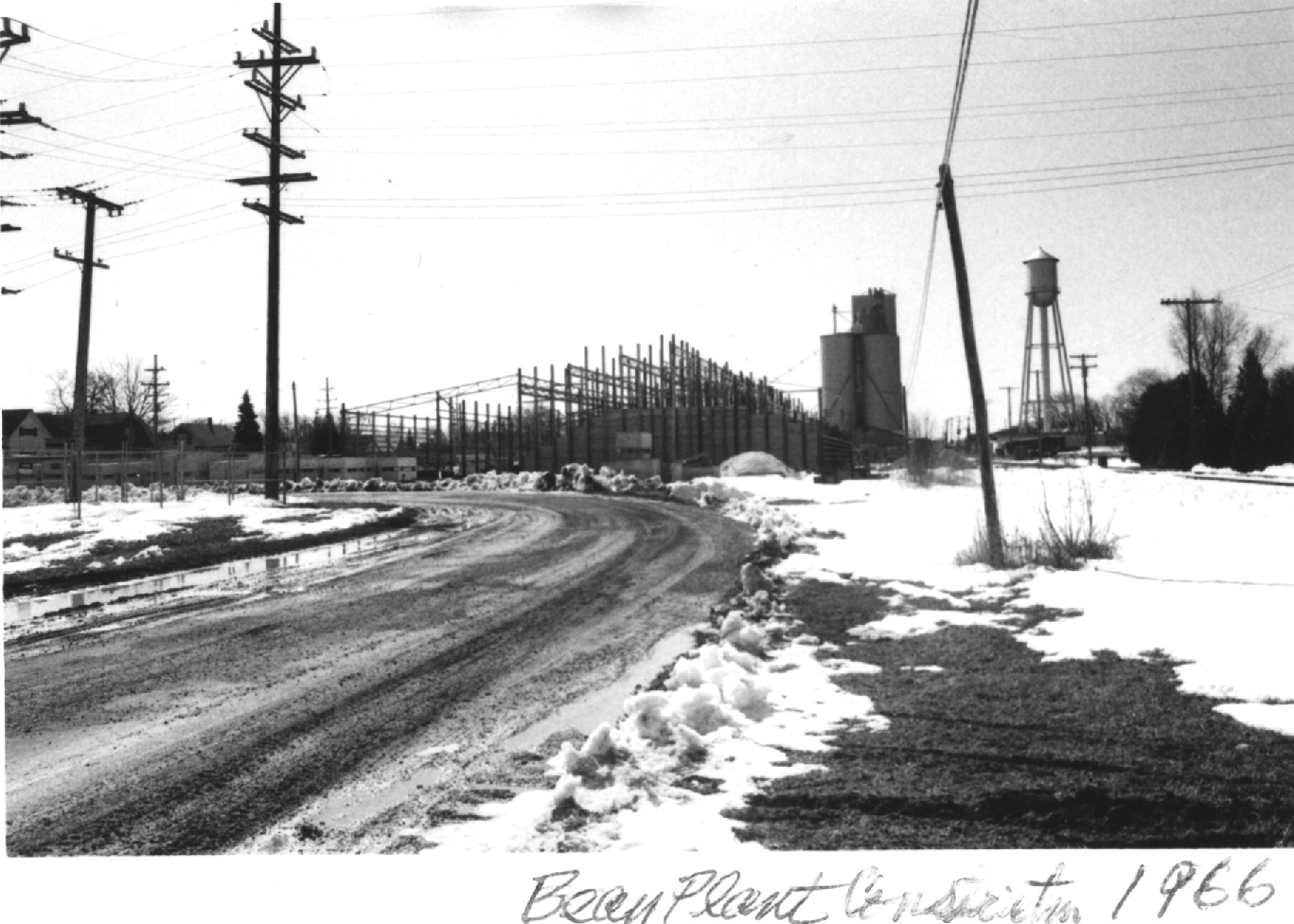

1966

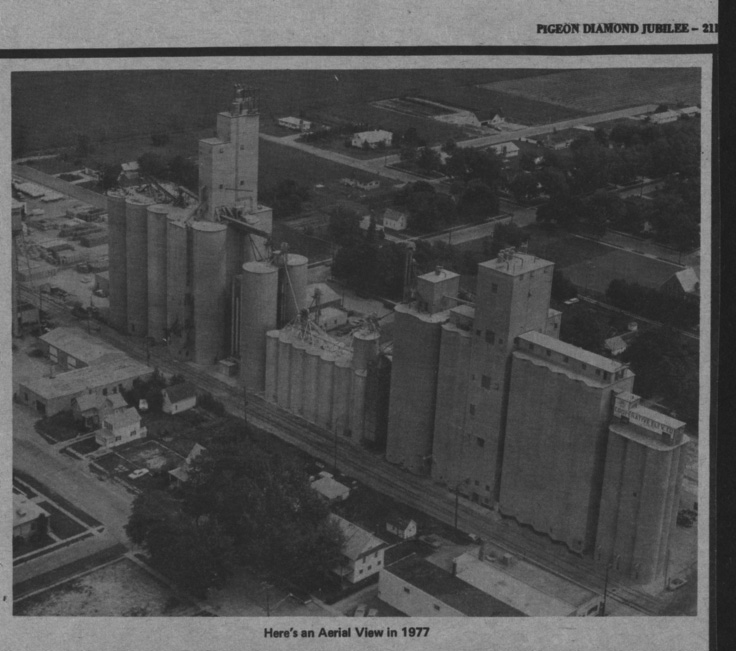

Construction of a bean processing plant with storage on Berne Street is completed. The company now ships over 500 rail cars filled with beans, wheat, and corn. The Cooperative has 27 silos with storage of 700,000 bushels.

1967

Al Roberts retires after 40 years of service, 28 years as General Manager. Norman Schulze becomes GM. Additional bean storage is added on Berne St. bringing capacity to 950,000 bushels.

1970

1974

General Manager Norman Schulze retires and Ted Leipprandt becomes the new GM.

1975

Construction of a bulk fertilizer blending plant begins. Also, the addition of a high capacity corn and wheat facility bring capacity to 1.6 million bushels.

1980

1981

Acquisition and renovation of the Akron Elevator added 100,000 capacity. At Pigeon, a new plant for dry beans was constructed. The plant will handle several varieties of dry beans. Total storage is now 3.8 million bushels.

1983

Acquisition of the Thumb Terminal east of Elkton offers additional receiving stations and storage. New silos were also constructed at Elkton bringing the Cooperative total capacity to 7.5 million bushels.

1985

The Sebewaing Farmers Coop and Cooperative Elevator Co. merge adding 700,000 in storage.

1987

Ted Leipprandt retires after 13 years of service. John Kohr becomes CEO. He forms a marketing department and asks Ted Leipprandt to manage this group. Ted stays until 1995.

1988

Acquisition of the Gagetown fertilizer plant.

1990

1990

Elkton Coop Farm Produce Co. unifies with Cooperative Elevator Co. bringing capacity to 11.1 million bushels.

1996

Cooperative Elevator Co. merges with Ruth Farmers Elevator. The company adds two additional members to the board (9 members). The capacity is now 13.6 million bushels.

2000

2000

Acquisitions of Bad Axe, Elkton, and Fairgrove fertilizer plants. Also, steel bins added to the colored bean plant. Storage is now 14.3 million bushels.

2001

John Kohr resigns after 14 years. Burt Keefer is now the CEO. At Ruth a steel bin is added bringing capacity to 14.8 million bushels.

2003

Pat Anderson becomes CEO. Cooperative Elevator Co. at this time is the largest grain, feed, and bean processing company in Michigan. It also ranks high throughout the United States.

2009

Acquisition of the North Branch plant. There is also another steel bin added at Ruth. Total storage is now 17.2 million bushels.

2010

2012

At Elkton Terminal a second scale, 30,000 bushel per hour pit, 300,000 bushel concrete wet bin and 1,000,000 bushel steel bin are added. This positions Cooperative Elevator Co. to have the fastest and most efficient state-of-the-art plant in the Thumb. Total Capacity is now 19.2 million.

Cooperative Elevator Co. and Central Valley Bean join together to form Alliance Valley Bean. Alliance Valley Bean purchased Larimore Bean Company in May 2012.

2013

A 769,00 bushel bin, a high speed unloading pit, a new rail load out system, and a 2nd scale was added at Ruth. A new 574,000 bushel bin was also added in North Branch. Grain storage is now 21.2 million bushels.

2014

At Akron a new 40,000 bushel rail load out system was added. An additional dryer and fertilizer dome was added at Elkton Terminal. A new dust system was also added at Ruth.

2015

A high speed dry bean receiving and shipping facility was added at Ruth.

Cooperative Elevator Co. celebrated 100 years of service.

2016

Scott Gordon is hired as the new CEO.

Acquisition of Organic Bean and Grain.

2018

At Ruth a new 1.2 million gallon 28% liquid fertilizer tank was added.

2020

2020

Cooperative Elevator Co. purchased 5 dry bean locations from Scoular Company (In Canada) to allow the Coop to expand its geographic footprint for edible beans. Cooperative Elevator Co. renames the company to Western Harvest Bean.

2021

Fairgrove upgraded to a 300,000 ton Dry Fertilizer storage facility.

2022

The Cooperative Elevator began working with agricultural drones in the spring of 2022. Our drones are equipped to offer both dry seed spreading using our dry spreader and liquid applications through their liquid tanks.We provide both dry and liquid application services and have accumulated over 25,000 acres of experience in this area.

2023

Colored Bean Plant expansion project finished. Adding 31,800 sq ft dock height with 2 additional docks for loading trucks and 1 rail dock for loading train cars. With this expansion Cooperative Elevator Co. upgraded the packaging and storage.